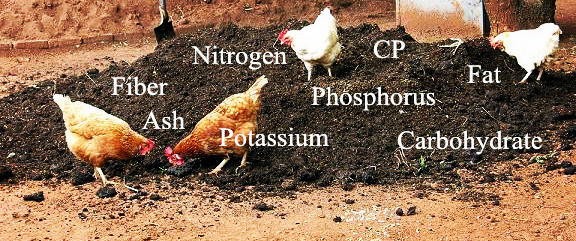

Chicken manure is a high-grade organic fertilizer. Feed are not being fully absorbed by chickens, 40%-70% nutrients being excreted to the outside of the body, so the nutrient content of chicken manure is the highest in all poultry manure. Nutrients content in chicken manure are as follows:

|

Crude Protein (CP)

|

Fat

|

Ash

|

Carbohydrate

|

Fiber

|

Nitrogen

|

Phosphorus

|

Potassium

|

|

18.7%

|

2.5%

|

13%

|

11%

|

7%

|

2.34%

|

2.32%

|

0.83%

|

The content of N,P,K is separately 4.1 times, 5.1 times, and 1.8 times of pig excrement. Sounds Interesting, right? However, there is lots of harm and risks

Chicken Manure Family Fermentation Methods

Households always face with problems to properly deal with household refuse, such as peels, leftovers, bones, cut flowers, filters, tea bags etc. For those who owns a small chicken farm, due to the small-scale production, it is not economic to specially purchase composting equipment for organic waste fermenting, so chicken waste management is also a big problem. With the introduction of advanced decomposition and fermentation technology, households are willing to compost and ferment daily waste themselves.

Some of them adopt Plastic-Bags Fermentation Method: placing the plastic bag with a circumference of 7-8m on the ground, one side being tied tightly with a piece of string, then bagging 150-200kg chicken manure on the other side (appropriate gap should be left in the bag). Adding water to the chicken manure till swamp them. Tighten bag, and after 5-6 days, chicken manure will be fully decomposed. It is suitable for farmers.

While others prefer to use earthworm as their “leavening agent”. Placing specially-bred earthworms inside the chicken manure, without fermentation. This method can save energy, taking advantage of natural ecological cycle. People can also add fermentabilitymicrobe into their chicken manure to achieve rapid deodorization and composting.

For many vegetable growers in China, they always build a big pond with 2m³volume. putting chicken manure in the pond, then adding fermentabilitymicrobe. After being fully decomposed and fermented, they can be directly applied to vegetables. During the decomposition of chicken manure, it will release heat and carbon dioxide, which is beneficial to vegetables. But growers have to be noticed of ammonia produced in the manure fermentation process.

Large-scale Chicken Manure Fermentation Process

As for the large chicken farms, there will be tons of chicken manure and chicken litter every day. For large-scale and large-amount chicken manure management, it is not efficiency and practical to adopt the above several methods. We should have the aid of composting equipment, such as hydraulic compost windrow turner, for quickly and sufficiently fermenting the chicken waste. According to the local temperature, chicken manure will become thoroughly decomposed within 7-12 days. Well-composted chicken manure could be sifted by screening machine to sieve tiny materials out, with bulk ones left. Those large manure particles need to be ground by crusher. This way, powder bio fertilizers are manufactured.

In my experience, most customers preferred to granulate powder fertilizers into granule ones, as chicken manure pellets are easy to transport and storage. Organic fertilizer dedicated granulator is the most suitable granulating machine in bio fertilizer production process.

Technological process for fermentation-flatland type

1.Piling chicken manure, house refuse, sludge and other organic materials on the flat ground. The width of the chicken manure pile should be same with the composting width of fertilizer turner machine (composting width differing with different compost turners), while there is no limit to the height and length of the manure pile, for example, the length could be 50m or 100m. Composting every 10,000 tons raw materials requires 5-6 acres lands (groove type compost turner occupies a little smaller area, comparing with hydraulic compost turner).

2.Turning all the organic raw materials (chicken manure, sludge, organic solid waste etc.) with composting equipment, such as hydraulic compost turner or auger type fertilizer turner. The moisture content of the compost pile should be between 50%-70%. Adding the pile with evenly-blended fermentabilitymicrobe to deodorize in 3-5 hours. 16 hours later, the temperature of the compost pile will up to 50°. Turn the organic pile again when the temperature increases to 55°. The most important function of compost windrow turners is to adjust the temperature and moisture of raw material pile by means of injecting more oxygen into the compost pile, for the purpose of sufficiently-decomposition. This is also called Aerobic Fermentation. Every time when the temperature up to 55°, turning the pile, to uniformly ferment the chicken manure pile, till it is thoroughly matured.

3.If the moisture content of the chicken manure or other organic materials is too high, you can add the manure pile with some dry accessories rich in organic matters to absorb water.

4.Generally, the chicken manure fermentation process takes 7-10 days. Due to various climate conditions, the fermentation time may be 10-15 days. The organic chicken manure fertilizer is odorless, non-germ, and with high humus content.

5.Powder manure fertilizer also could be granulated into granule bio fertilizers by organic fertilizer granulator, such as disc pan granulator, organic fertilizer dedicated granulator, or flat die fertilizer pellet mill. See our 50,000 tons organic fertilizer production process. This bio fertilizer production line includes detailed information on all fertilizer equipment needed, and how those machines should be used.

1.Drying the fresh chicken manure to control its moisture content ≤ 50%. Filling the fermenting pool with plenty of chicken manure. Adjuvant organic materials, such as wood shavings, Zeolite powder, rice husks, also could be added. Thickness of the manure pile should be 1.5-1.6m. Notice: the moisture content of all organic materials should be kept below 50%. Using forklift to evenly mix the organic raw materials.

2.Turning the chicken manure everyday with groove type compost turner or auger type turner. Simultaneously, evenly spraying bacterial liquid on the manure pile to make them fully composted, sterilized, deodorized, and dewatered. Moisture content of mature organic materials is always between 30-35%. The whole process will lasts for 10-15 days.

If a chicken farm has 100,000 chickens, the manure fermentation will need 3-4 fermentation tank (depending on the length of fermentation tank). Each tank should be equipped with one set of composting equipment for daily materials-turning work-twice a day.

Benefits of Organic Chicken Manure Fertilizer

Main substance of chicken manure is organic matter. It can increase soil organic matter content to apply organic chicken manure fertilizer. As we all know, organic matter can improve soil physical, chemical and biological properties, improve agricultural ecological environment, so chicken manure benefits the soil a lot. Chicken manure fertilizer suits to kinds of crops and cash crops, such as watermelons, vegetables, orange, citrus, tea, tobacco, nursery stock, ginger and garlic, bamboo shoots, strawberry, litchi, longan, banana, grapes, wheat, corn, sorghum, soybeans, rice.