Semi-wet material crusher is one of common fertilizer machines. As with other machines, it needs to maintain and repair when it is used in feritlizer production, so that it can prolong service life of the machine. How to maintain semi-wet material crusher? There are several points for attention in the installation of this fertilizer crusher.

a.Semi-wet material crusher should be installed on the concrete in the horizontal level that is pouring in advance. And then fix it on foundation bolt.

b.While installing the machine, the installation personnel are supposed to ensure that the main machine body is perpendicular to horizontal plane rather than slant.

c.After semi-wet material crusher installation, check bolt in each parts to infirm whether it is loose and bin gate of main engine is tight.

d.Configure power line and control switch in accordance with power of the equipment in order to make power load regular within safe rage.

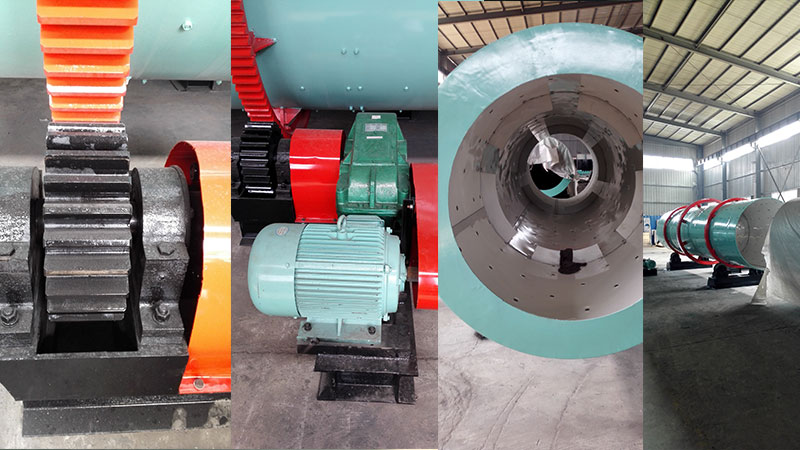

e.Check lubrication system between bearing and wheel gear of the machine carefully. It demands that injected engine oil is clean without sundries. In the meantime,

sealing is good and there is no oil leaking.

FAQs:

1.Why is current unstable while feeding?

Current reflects the burthen of fertilizer crusher. Erratic current shows that feeding system is wrong. However, feeding frequency is constant, indicating that the volume of feed is unchanging. Because semi-wet crusher is a special fertilizer machine, it can run with two direction whirl fashion. Thus, the problem is caused by inconsistency of the direction of feed and working. Before feeding, it is necessary that observes the directing of rotation. And then keeping a consistent direction of these two operation can solve the above problem.

2.It blocks discharge hole of semi-wet material crusher. How to remedy the trouble?

Overly rapid feed rate and poor pipe make the air outlet of semi-wet material crusher blocked. Mismatching with conveyor leads to decreasing wind in the discharge pipe, thus bunging up the pipe. After detecting defects, the serviceman should clean up conveyor that is mismatched with feed-through machine and adjust charging rate, which ensures normal operation of equipment.

We still need to pay attention to breaks and aging of hammer, blockaded and ragged of screen hole. High moisture content of the material enables to make semi-wet material grinder blocked. Update aging and serious breaking hammer periodically can not only increase production efficiency, but also prevent semi-wet material grinder blockage. Moreover, it enhances production reliability and and produces good raw materials for fertilizer granulator.

3. Once open control system, it is tripped. How to maintain semi-wet material crusher and solve the problem?

Trip is caused by a short circuit. It does not trip when semi-wet material crusher is not starting up. As long as it is starting up, it is tripped. It is caused by vibration after starting semi-wet material grinder. Therefore, it is most likely because the door protection or positive and reverse rotation position limit switch sheel or loose wiring, bringing about tripping due to a short circuit. The operator can check the wiring to close the circuit.

4. Semi-wet material crusher picks up when it starts the star contactor, but it does not pull with the positive and negative main contactor .

It mainly because reverse rotation position limit switch is inconsistent with reverse rotation position option switch. On the other hand, it is relevant to unpressed or

damaged switch.

5. What is the reason of sudden decrease in output of this fertilizer crusher?

(1) Check its current situation, ensuring it reaches rated current.

(2) Check the device assembly to make sure whether it is reasonable.

(3) Examine direction of feed and affirm whether it is consistent with the direction of the guide plate.

(4) Detect air volume of draught fan whether reach the requirement of rated air flow.

6. It sprays materials in the feed port or stores a lot of materials in the crushing room. What is the reason for the failure?

(1) It is spraying materials, which may be related to unreasonable interval of hammer. It mainly because the gap is too large, resulting to spraying materials.

(2) Another reason is that the semi-wet material mill feed direction is inconsistent with the running direction. In the opposite direction, semi-wet material crusher hammer collides with the material, making some material erupted. It will accumulate a lot of materials inside the grinding chamber after a long time.

7.In the process of semi-wet material mill startup, sometimes it suddenly shuts down, and then it can start after the boot. What is the trouble?

The serviceman should analyze the problem from the perspective of operating principle. Now that it can start up, it is in the normal state of control system. However, it suddenly halts during startup at times, indicating that this phenomenon is resulting from the vibration after the semi-wet material grinder boot.

8. It is difficult to work in working order. The machine can’t run normally.

Firstly, check outlet, plug and power lines of the semi-wet material mill to make sure whether they are not falling caducous or broken. After troubleshooting above problems, the service man can plug in the power to test semi-wet material mill. The motor power does not rotate in an energized state. However, it can turn when toggle wheel by hand. It can be concluded that there is capacity failure of two pieces of start-up capacitance. In this case, change a new capacitor and then it can solve the problem perfectly.

9.The current noise is too large so that the motor can not start. How to examine and repair?

In this case, it is related to short circuit of starting capacitance and motor coil. Without professional instrument, the maintainer can remove the capacitor firstly. Plug the two lead wires into the power of the zero line and live wire to charge the capacitor, and then remove the lead two short circuit to discharge. It can send sparks and has a loud “pop” sound, indicating that the capacitor can be used. If sparks and sound are very weak, indicating that the capacity of the capacitor has fallen. It needs to be renewed or add a small capacitor. If the capacitance is damaged, it needs to replace the new machine with the same specifications.