Research shows that organic fertilizer can effectively increase crop yield per acre by approximately 30% and requires approximately 90% less fertilizer per acre than inorganic fertilizer. Organic fertilizers also return valuable nutrients to the soils and improve cohesion, reducing runoff of fertilizer. So, organic fertilizer plants are booming in the world. The following tips can help you establish an available organic fertilizer plant.

1 Market research

Without proper research and study in your region, it is immature for you to start now.

First, it is necessary for you to research present demand and supply. If local organic fertilizer supply is over demand, you’d better not to do it now. On the contrary, if it is demand over supply, then you can start immediately to get more market shares and opportunities.

Second, you must look for organic raw materials sources. Raw materials are the first step of a factory. So part of what you should study during your research is to pin the best and most suitable raw materials that you can work with.

You can talk to poultry farmers or industrial managers or governmental authority to collect these materials, keeping a steady flow to your fertilizer producing on going.

2 Register Your Business and Obtain Your Business Permit and Operating License

In fact, you cannot start an company without getting approved the local regulating authority in the world. That is to say, you need register your fertilizer plants with the government of your country and obtain a business permit and operating license. Without these, your illegal company will face the threat of law.

3 Location of fertilizer manufacture

When choosing a proper location for organic fertilizer plant, smell pollution and traffic transportation are the problems you must think about. Recent study shows that fertilizer plants are best situated in closed proximity to the supply of raw materials for fertilizer production, while far away from residential area because of smell pollution. While, the traffic network must be well for raw materials transportation.

4 Plant size

Company size always depends on the balance between expected production and cost profit, but fertilizer plant is different. By limitation of raw materials supply and location of materials fermentation, fertilizer plant is often small and medium size in china. Fund investment and cost control are also the reasons limit your fertilizer plants size.

Taking our 50,000 tons organic fertilizer plant as an example, the available plant size is approximately 30-40 hectares, including 8-10 hectares of materials fermentation area and other areas for raw materials storage and fertilizer storage and fertilizer producing. Often, some fertilizer plants built two or more indoor composting pins for investment. An indoor composting pit, with a combination of compost turner and pit composting system, produce high levels of output and the investment in this equipment would be recouped within five years. In addition, to reduce cost, most fertilizer plants collect raw materials nearly, ferment and then process nearly.

5 Manufacturing technology

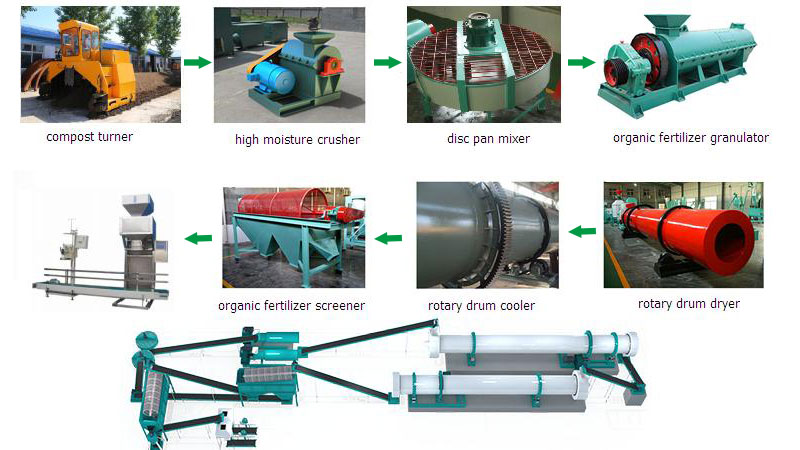

As a key part of an organic fertilizer plant, produce technology decides firm’s cost and profit. As a matter of fact, a whole manufacturing process in an organic fertilizer plant includes:

- Application of compost turner to shorten fermentation time of organic raw materials ;

- Manufacturing process of blending and crushing and drying materials before fertilizer granulation ;

- Application of pan granulator or new-type fertilizer granulator to complete raw materials granulation process;

- Fertilizer coating and packaging.

6 Choose a proper bio fertilizer production line

It is better to choose a suitable fertilizer production line according to plant size and expected organic fertilizer production. We now provide bio fertilizer production lines including 20,000 tons bio fertilizer production line, 30,000 tons bio fertilizer production line and 50,000 tons bio fertilizer production line. In the same time, we can manufacture other fertilizer production lines according to your requirements.

Taking a 50000 tons organic fertilizer production line as an example, it consists of many fertilizer machines, such as compost turner, materials blender, crusher, granulator, rotary dryer,cooler, coating machine and packaging machine.

7 Marketing and promoting

Advertising on newspapers and fertilizer magazines can help you attract more farmers and distributors. By the way, you should pay attention to fertilizer packaging. The foul smell from organic fertilizer can be well taken care of if proper packaging is done. We believe that the quality is the soul of an enterprise. Therefore, you should always put quality as the first consideration. That will help you accumulate more loyal guest source.

These 7 surefire tips is a great deal of respite for starting an organic fertilizer manufacturing company from the scratch, and then build it to profitability with the shortest time frame possible.