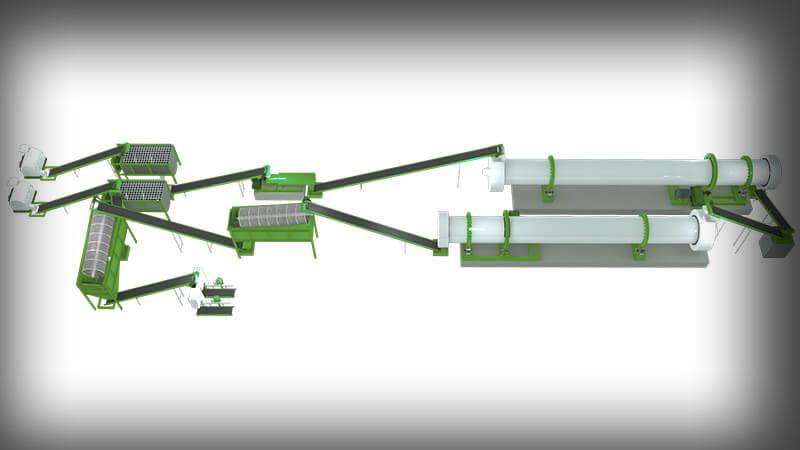

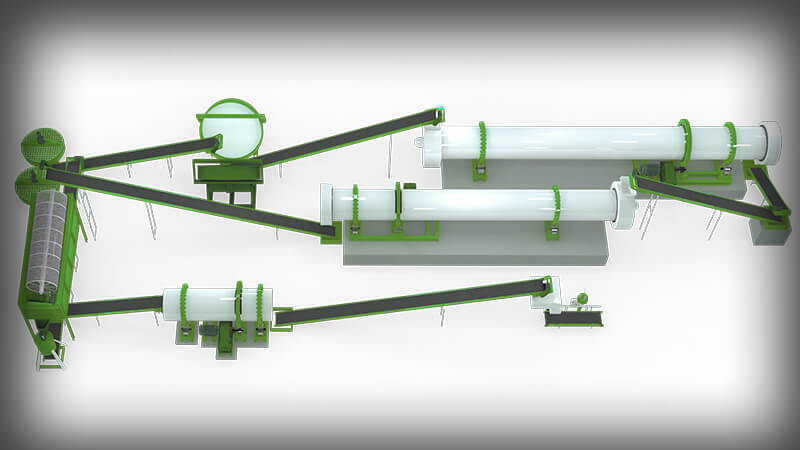

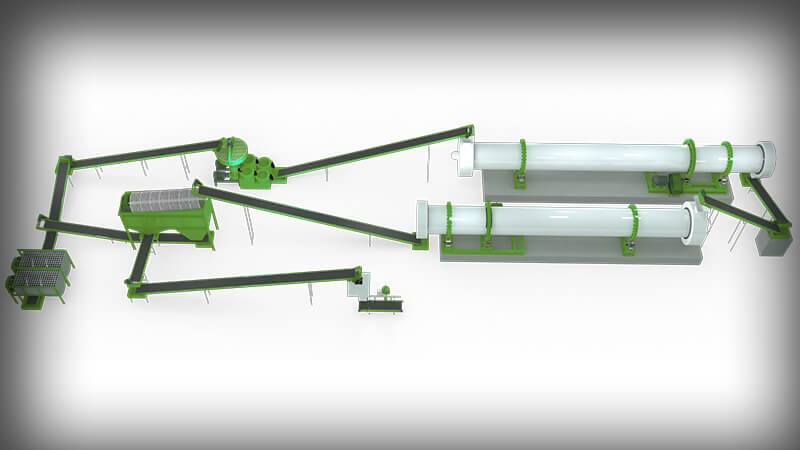

Introduction of 50,000 Tons Organic Fertilizer Plant

The organic fertilizer production line is mainly used to produce different organic materials that are derived from animal waste, industrial waste, household waste and municipal sludge, etc. It not only reduces environment pollution, but also makes rational use of resources. The organic fertilizer

Working Process of Organic Fertilizer Production Line

1.Fermentation process: Fermentation is the basic process of production. Moisture, temperature and time need to be strictly controlled. Compost turner is the organic fertilizer machine used to accelerate the fermentation of microorganisms and improve the quality of compost. Our compost turner can be used under this condition. Self-propelled compost mixer turner or hydraulic compost turner can meet the needs in different environments.

2.Crushing process: Lump materials should be crushed after the fermentation process. It is difficult to make the matter into granules manually. In this way, it is necessary to use fertilizer crusher. We recommend customers to choose high moisture materials crusher machine, as it can crush semi-wet materials, and with high crushing efficiency.

3.Mixing process: According to the overall layout of this production line, flat pan mixer is used in the mixing process.

4.Granulation process: It is the important production process in the whole production line. According to different requirements, nutrients can be added. Spherical particles are processed, saving plenty of energy. Therefore, choosing the proper organic fertilizer machine is particularly essential. New type organic fertilizer granulator is the most suitable machine.

5.Drying process: After granulating, the granules are in need of drying. The moisture of organic fertilizer is reduced 10-40%. Rotary drum drying machine is an equipment to reduce the moisture of the particles, which is feasible for organic fertilizer production.

6.Cooling process: In order to ensure quality, the particles should be cooling after drying with the help of rotary drum cooling machine. And then the cooling effectiveness is raised.

7.Screening process: There are unqualified organic fertilizers during production. It needs rotary drum fertilizer screening machine to separate the rejected goods from standard substance.

8.Packaging process: Fertilizer packaging machine is used for packing processed fertilizers. We can use packing machine to pack and bag the particles.It can achieve pack products automatically and efficiently.

Advantages of 50,000 tons Organic Fertilizer Production Line

1.Choosing animal waste and municipal waste as raw materials is friendly to environment, which greatly reduces pollution.

2.The production is in low investment and high profit. It is beneficial to promote innocent treatment of waste, utilize resources rationally.

3.The whole production process is in easy operation, high-efficient production and stable performance. It is helpful to realize industrialization, marketization, and large-scale production.

4.With advanced technology, the quality of organic fertilizer is improved, promoting commodification.

Working Video of Making Organic Fertilizer Granules and Bio Fertilizers

Application of Organic Fertilizer Production Line

1. Agricultural waste: corn stalk, wheat straw, leaves,etc.

2. Animal waste: chicken manure, pig manure, horse dung, sheet manure and shard, etc.

3. Industrial waste: vinasse, begass, corn grit, etc.

4. Household waste: pericarp, vegetable leaves, leftpvers and eggshell, etc.

5. Municipal sludge: domestic sewage, industrial sewage, water supply sludge and river sludge, etc.

Technical Data of 50,000 tons Organic Fertilizer Production Line

|

Item

|

Model

|

Overall Dimensions

L x W x H(mm)

|

Prod Capacity

(t/h)

|

Power

(kw)

|

Quantity

(set)

|

|

Flat Pan Mixer

|

AZS-YPJB-2000

|

2100x2100x1600

|

3-6

|

11

|

2

|

|

New Type Fertilizer Granulator

|

AZS-JCZL-80

|

4160x1660x1170

|

3-5

|

55

|

2

|

|

Rotary Drum Dryer

|

AZS-HGJ-2.0

|

21500x4170x2600

|

8-14

|

37

|

1

|

|

Rotary Drum Cooler

|

AZS-LQJ-1.8

|

21500x4170x2600

|

8-14

|

22

|

1

|

|

Rotary Drum Screening Machine

|

AZS-GTSF-1.5×5

|

6300x1880x3450

|

3-7

|

7.5

|

2

|

|

Vertical Crusher

|

AZS-LSFS-60

|

1000X730X1700

|

1-5

|

15

|

1

|

|

Finished Products Warehouse

|

AZS-CPC-2.0

|

2150x2150x4100

|

8-15

|

2

|

|

|

AZS-DGS-50F

|

3-8bag(s)/minute

|

1.5

|

2

|

||

|

Belt Conveyor

|

9

|

||||

|

Dust Settling Chamber

|

Drawing is provided

|

1

|

|||

|

Hot Blast Stove

|

Drawing is provided

|

1

|

NOTICE: This production line is for your reference only. Engineers and sales persons will specially design for you in accordance with your raw materials, self construction of factory building and capital budget.

Extension Reading: How to Establish An Organic Fertilizer Production Line?