Introduction of 20,000 Tons Organic Fertilizer Production Line

For many entrepreneurs who begin to start bio fertilizer production, it would be difficult for them to completely know the whole process and find the best match of each machine. According to doubles years of experience and customers’ need, we push out this 20,000 tons/year organic fertilizer production line. It is centralized controlled and highly automatic. More than that, Azeus organic fertilizer production line very stresses saving energy. The fermentation system can make integrated utilization of solar energy, bio-energy, and mechanical energy.

Application of 20,000 Tons Organic Fertilizer Production Line

This bio fertilizer plant is mainly for organic fertilizer production. The raw materials of this

Agricultural waste: straw, dregs of beans, cotton dregs,etc

Animal manure: mixture of poultry litter and animal waste, such as cattle manure, chicken manure, waste of fish market,etc

Industrial Waste: wine lees, vinegar residue, manioc waste, sugar scum,etc

Home Scrap: food waste, roots and leaves of vegetable

Sludge: the sludge of the river,sewer, etc.

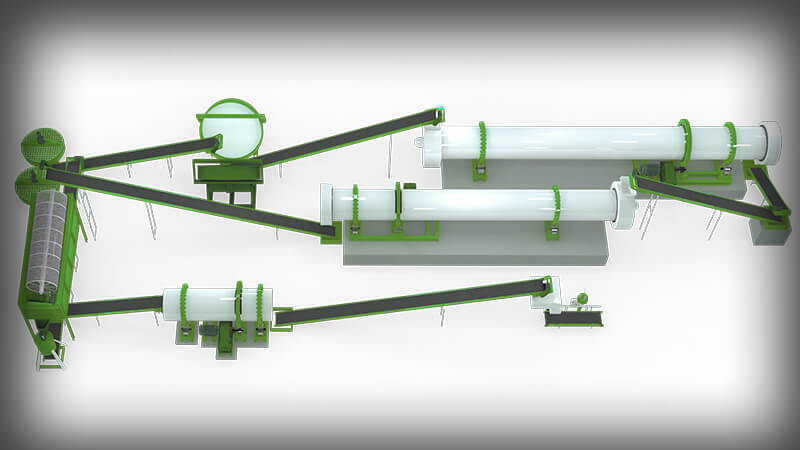

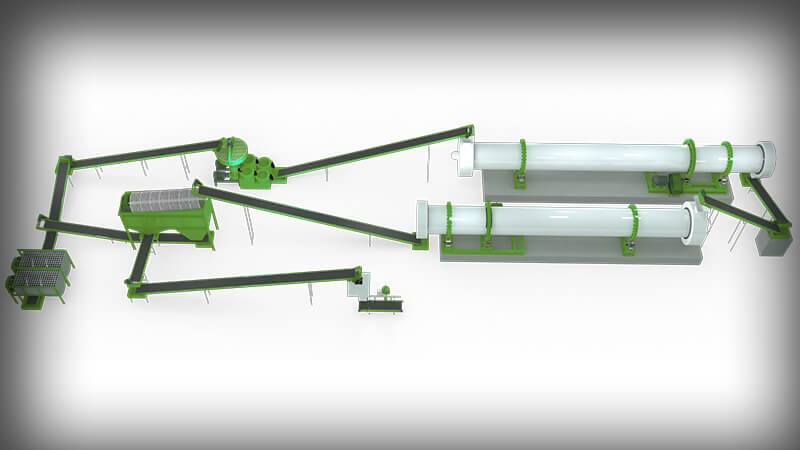

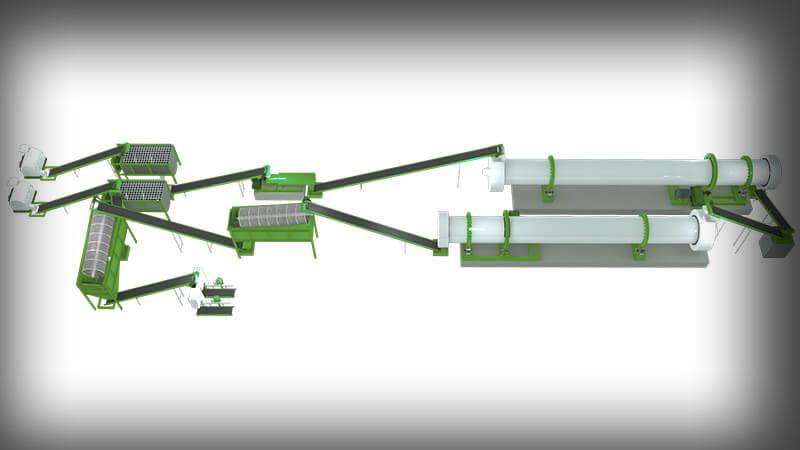

Main Parts of 20,000 Tons Organic Fertilizer Production Line

A complete organic fertilizer production process includes fermentation, crushing, mixing, granulating, drying and cooling, screening and packaging. The correspondent fertilizer machines needed in each process are double helix compost turner, pan feeder, semi-wet fertilizer crusher, disc granulator, rotary drum dryer, rotary drum cooler, drum sifting machine, organic fertilizer coating machine, automatic packing machine, vertical crusher,belt conveyor.

Now, let’s have a overall view of each step:

1.Fermentation process

The fermentation of organic materials plays an important role in the whole production. Whether the fermentation is sufficient greatly influences the quality of the end product. We choose double helix compost turner for you, which not require too much for the working places. Of course, we also can make change if you have other requirements.

2.Crushing process

3.Mixing and Granulating Process

After being crushed, raw materials should be mixed evenly, then go to granulating process. Granulating process is a core part in the production line. Here we choose pan granulator for you, which is of low output requirement. Under the continuous rotation of the disc, fermented raw materials are uniformly bonded together. You also can choose an automatic cleaning equipment for improving the lifespan of the granulator machine, which can be installed in the upper part of the pan granulator.

4.Drying and cooling process

In fertilizer production, rotary drum dryer and rotary drum cooler are usually combined together. With these two kinds of machines, the humidity of fertilzier particles will be reduced to 2%-5% with no dust and proper temperature to store.

5.Screening process

After cooling, there are still big particles or powered material in the end products. They all can be screened out by using Azeus rotary drum screening machine, then they will be returned to the second granulating or mixing with raw materials. Now, a complete production cycle is finished.

6.Packaging Process:

Our fertilizer packager is an automatic and intelligent fertilizer machine, which has strict weight control system and is adapted to different irregular materials and granule materials. It is a best choice for sub packaging of large amounts of bulk materials because of its high efficiency.

Nowadays, organic farming is praised highly and the need of bio-organic fertilizer must will increased. With high output and high quality of finished fertilizer, this fertilizer production line has a very good market prospect. Come on to choose it!

Technical Data of 20,000 tons/year Bio Fertilizer Plant

|

Item

|

Model

|

Overall Dimension

L*W*H(mm)

|

Prod Capacity

(t/h)

|

Power

(kw)

|

Quantity

(set)

|

|

Pan Feeder

|

AZS-YPWL-200

|

2100*2100*1300

|

2.5-5

|

5.5

|

2

|

|

Pan Granulator

|

AZS-YPZL-3000

|

3420*2480*2870

|

1.5-3

|

11

|

2

|

|

Rotary Drum Dryer

|

AZS-HGJ-1.5

|

16300*2800*2260

|

3-5

|

11

|

1

|

|

Rotary Drum Cooler

|

AZS-LQJ-1.2

|

16300*2800*2260

|

3-5

|

7.5

|

1

|

|

Rotary Drum Screening Machine

|

AZS-GTSF-1.5*5

|

6300*1800*3450

|

3-7

|

7.5

|

2

|

|

Rotary Drum Coating Machine

|

AZS-HBM-.2*4

|

2-4

|

7.5

|

1

|

|

|

AZS-LSFS-60

|

1000*730*1700

|

1-5

|

15

|

1

|

|

|

Finished Products Warehouse

|

AZS-CPC-2.0

|

2150*2150*4100

|

8-15

|

2

|

|

|

Automatic Packager

|

AZS-DGS-50F

|

3-8 bags/minute

|

1.5

|

2

|

|

|

Belt Converyor

|

8

|

||||

|

Dust Settling Chamber

|

Drawing is provided

|

1

|

|||

|

Hot Blast Stove

|

Drawing is provided

|

1

|

NOTICE: This production line is for your reference only. Engineers and sales persons will specially design for you in accordance with your raw materials, self construction of factory building and capital budget.