Introduction of 50,000 Tons/year NPK Fertilizer Production Line

This compound fertilizer production line is mainly used to manufacture NPK compound fertilizers. With a high production capacity of 50,000 tons per year, it can meet the demands of large fertilizer factories. In the granulation process, we choose pan granulator as it is with high efficiency and can

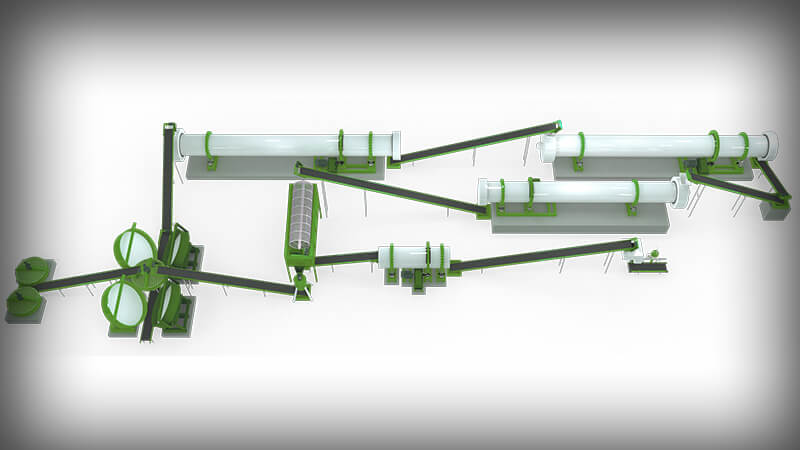

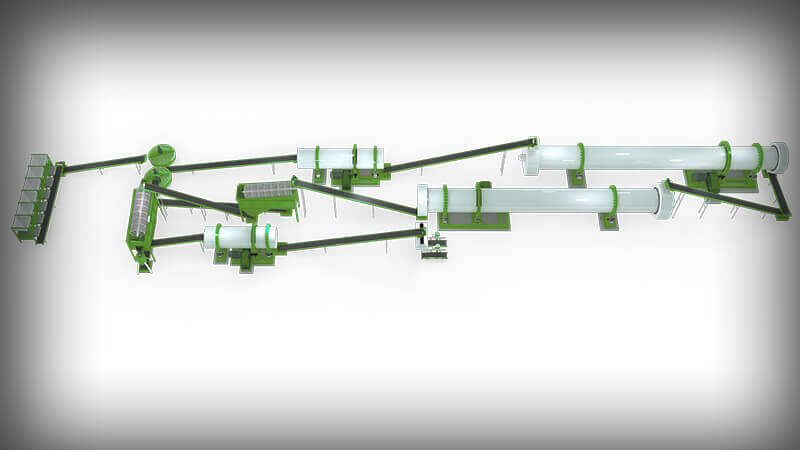

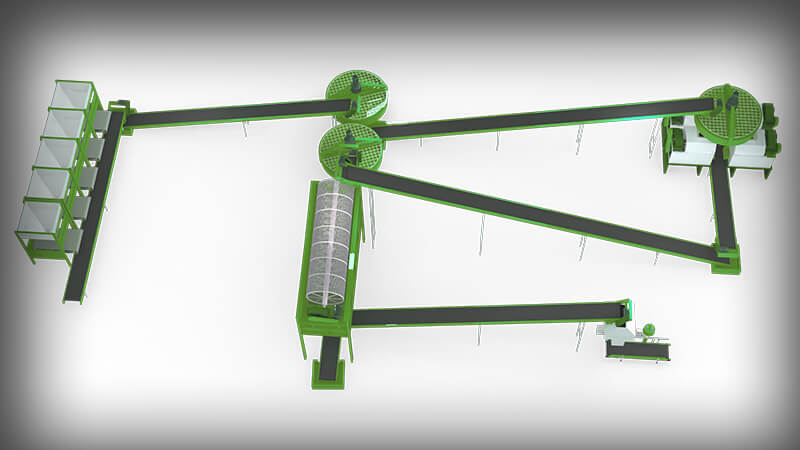

Main Components of 50,000 Tons/year NPK Fertilizer Production Line

There are twelve main components of pan granulator compound fertilizer production line, including pan feeder, pan mixer, chain crusher, pan granulator, rotary drum dryer, rotary drum cooler, rotary drum screening machine, finished products warehouse, automatic packager, belt conveyor, dust settling chamber, and heat exchanger.

As their name says, the pan feeder is used in putting materials in the tank; the pan mixer is used in stirring the raw materials; the chain crusher is responsible for crushing; the pan granulator works for granulating; the rotary drum dryer is an drying machine; the rotary drum screening machine is in charge of grouping the qualified or unqualified products; the finished is used for storage; and the automatic packager is responsible for packaging the finished products.

50,000 Tons NPK Fertilizer Manufacturing Process

1.The batching machine rations the raw materials in accordance with the formula. The raw materials for making fertilizer are mainly ammonium nitrate, urea, ammonium chloride, ammonium sulphate, ammonium phosphate, ammonium phosphate, potassium chloride, potassium sulfate and the like.

2.Then the pan mixer blend the materials fully by its agitating arms and small blades.

3.The belt conveyor transit the materials into crusher machine for breaking the materials into small pieces to meet the demanding size of granulator.

4.The fertilizer granulator is powered by the transmission device, and the rotary scrapper over the round disc can process the fertilizer into preset shapes, as well as clean up the granules at the bottom of the disc. You can preset the size of the granules by adjusting the height of the round disc rims.

5.Next, the granules go through the drying and cooling phase. During this process, the drying machine removes extra moisture from the granules to increase its density, and it’s also conducive to store them.

6.The rotary drum takes the charge of classifying the qualified or unqualified granules. The qualified ones will be conveyed into the finished product warehouse. And the unqualified ones will be sent back for recycling.

7.The automatic fertilizer packer pack the finished products efficiently.

Application of 50,000 Tons/year NPK Fertilizer Production Line

Granulation, also described as agglomeration, or balling, is a process of the cohesion of fine particles into larger granules with defined mechanical strength. The agglomeration of fine particles of the materials as a result of physical and chemical mechanisms of binding. Granulator has a large scope of application in many industries, such as mineral processing, food processing, agriculture, detergent chemistry, pharmaceutical enterprises, especially in fertilizer factories. Our NPK fertilizer production line is designed on advanced theory. The method is attractive in terms of cost-effectiveness in light of low investment and exploitation expenses.

Features of 50,000 Tons/year NPK Fertilizer Production Line

1.Our granulator machines adopt high-strength, anti-corrosive materials, which is adaptive to hostile working environment.

2.Relatively simple structure is easy to operate and maintain, and it’s easy to adjust the machines to your specific demand.

3.High granulating efficiency, reliable performance, and long service life.

4.The pan granulator compound fertilizer production line is can be used in producing compound production line, as well as in manufacturing organic fertilizer, inorganic fertilizer, bio-fertilizer and magnetizing fertilizer etc.

5.We can design the granulator compound fertilizer production line in accordance with your requirements.

Technical Data of 50,000 Tons/year NPK Fertilizer Production Line

|

Item

|

Model

|

Overall Dimensions

L x W x H(mm)

|

Prod Capacity (t/h)

|

Power (kw)

|

Quantity (set)

|

|

Pan Mixer

|

AZS-YPJB-2000

|

2100x2100x1600

|

3-6

|

11

|

2

|

|

Pan Feeder

|

AZS-YPWL-2000

|

2100x2100x1300

|

2.5-5

|

5.5

|

1

|

|

Pan Granulator

|

AZS-YPZL-3200

|

3600x2700x3200

|

2-4

|

15

|

4

|

|

Rotary Drum Dryer

|

AZS-HGJ-2.0

|

21500x4170x2600

|

8-14

|

37

|

2

|

|

Rotary Drum Cooler

|

AZS-LQJ-1.5

|

19500x3300x2450

|

6-10

|

11

|

1

|

|

AZS-GTSF-1.5X5

|

6300x1880x3450

|

3-7

|

7.5

|

1

|

|

|

Middle Finished Products Warehouse

|

AZS-CPC-2.0

|

2150x2150x4100

|

8-15

|

2

|

|

|

Middle Automatic Packager

|

AZS-DGS-50F

|

3-8bags/minute

|

1.5

|

2

|

|

|

Chain Crusher

|

AZS-LSFS-60

|

1000x730x1700

|

1-5

|

15

|

1

|

|

Belt Conveyor

|

10

|

||||

|

Dust Settling Chamber

|

Drawing is provided

|

3

|

|||

|

Heat Exchanger

|

Drawing is provided

|

2

|

NOTICE: This production line is for your reference only. Engineers and sales persons will specially design for you in accordance with your raw materials, self construction of factory building and capital budget.