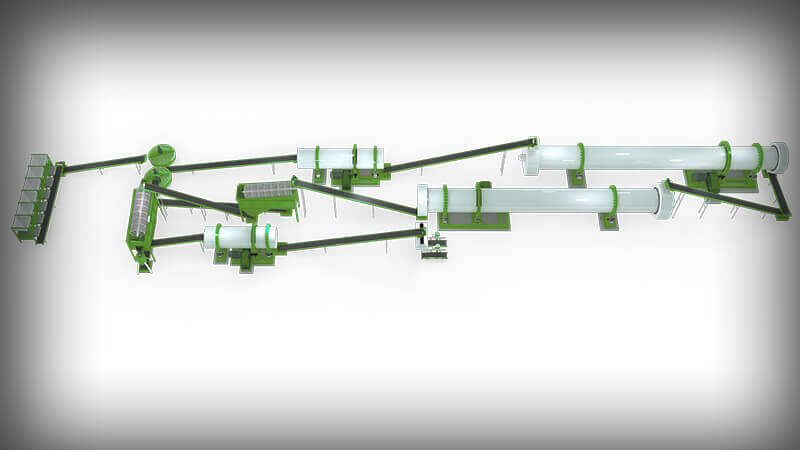

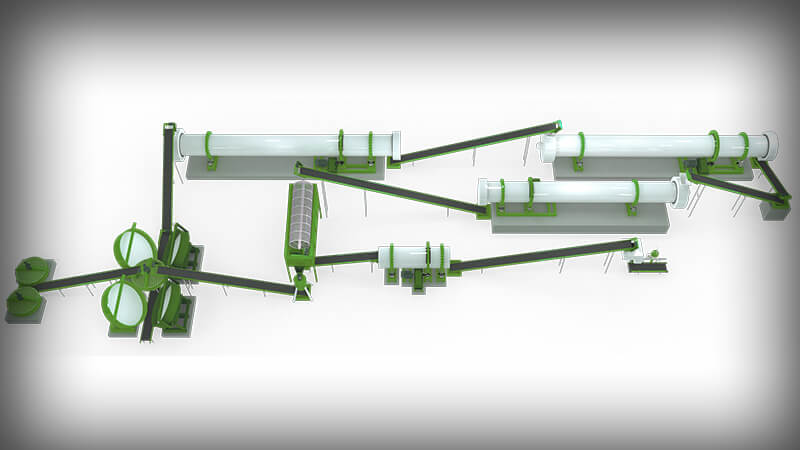

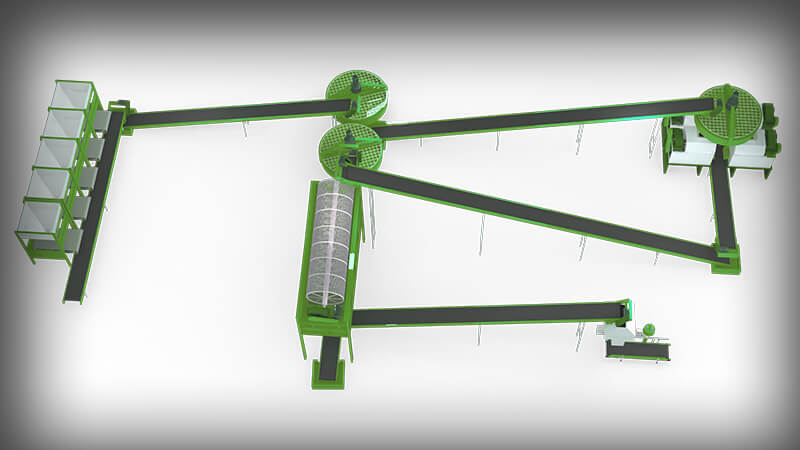

Introduction of 100,000 tons Compound Fertilizer Production Line

This NPK compound fertilizer production line meets the need of most customers, being a large capacity production line and having earn great popularity

We choose Rotary Drum Granulator as the main fertilizer making machine, as it is the most desirable equipment for large-scale high and low concentration compound fertilizer production.

Productive Technology of NPK Compound Fertilizer Production Line

This compound fertilizer making system has low demand on formula. Steam whose pressure is in 4-6kpa, is introduced into rotary drum granulator, then being mixed with powder Phosphorus, Potash or other Nitrogenous manure, conditioning agents for further granulating. The steam melt the surface of N to make N bind with other raw materials. This compound fertilizer production line would be particularly applicable in high N compound fertilizer. It can produce all kinds of fertilizer, concentration varying from 25% to 48%. Due to the moisture content of materials being 3-5% during granulation, the drying capacity improves by 20%-40%, which greatly increase fertilizer production and decrease consumption.

Technological Procedure of 100,000 Tons Compound Fertilizer Production Line

The whole compound fertilizer production process: raw materials batching, raw materials mixing, granulation process, drying process, cooling process, screening process, coating process and packaging process.

Raw materials batching:

Raw materials, such as ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (for monoammonium phosphate and diammonium phosphate, heavy calcium and Calcium Superphosphate ), KCL (potassium sulfate), are batched in definite proportions (according to market demand and local soil test results).

Raw materials mixing and granulation:

Mixing the raw materials evenly to improve the nutrient content of granular fertilizers. After being mixed well, transport the raw materials into rotary drum granulator for granulation: introducing vapor and gaseous ammonia, or adding orthophosphoric acid, ammonium phosphate slurry, nitrogen solutions, calcium carbonate slurry, a series of chemical reaction occurring in the drum. A small amount of water can be added in the whole

Fertilizer granules drying and cooling:

Transferring the NPK fertilizers into rotary drum dryer to dry out the water containing in the fertilizer granules, increasing the fertilizers intensity. After being dried, due to the high temperature, fertilizers are easy to cake, so NPK granular fertilizers need to be cooled for easy to storage and transport. We choose rotary drum cooler, as it is with high efficiency, and great hourly output.

NPK fertilizer granules screening and packaging:

Screen the fertilizer granules. Sub-standard fertilizers should be regranulated, and standard NPK fertilizers can be coated to increase the brightness, and then be packaged by automatic fertilizer packing machine.

Working Video of NPK Compound Fertilizer Production Processes

Technical Data of NPK Compound Fertilizer Production Line

|

Item

|

Model

|

Overall Dimensions

L x W x H(mm)

|

Prod Capacity

(t/h)

|

Power

(kw)

|

Quantity

(set)

|

|

Six Bin Batching Machine

|

1

|

||||

|

Pan Mixer

|

FY-WSJB-90

|

2330X1070X1200

|

3-5

|

15

|

2

|

|

Rotary Drum Granulator

|

FY-ZGZL-22X80

|

8000x4300x3700

|

15-20

|

45

|

2

|

|

Rotary Drum Dryer

|

FY-HGJ-2.4

|

26000x2900x2900

|

20

|

45

|

1

|

|

Rotary Drum Cooler

|

FY-LQJ-2.2

|

23500x2600x2600

|

20

|

30

|

1

|

|

Rotary Drum Screening Machine

|

FY-GTSF-2.0X8

|

9800x2700x4700

|

20

|

15

|

2

|

|

Rotary Drum Coating Machine

|

FY-HBM-1.8X7

|

5-8

|

15

|

||

|

Chain Crusher

|

FY-LSFS-80

|

1250x1000x2100

|

2-8

|

22

|

1

|

|

Finished Products Warehouse

|

FY-CPC-2.0

|

2150x2150x4100

|

8-15

|

2

|

|

|

Automatic Packager

|

FY-DGS-50F

|

3-8bags/minute

|

1.5

|

2

|

|

|

12

|

|||||

|

Dust Settling Chamber

|

Drawing is provided

|

2

|

|||

|

Hot Blast Stove

|

Drawing is provided

|

1

|

NOTICE: This production line is for your reference only. Engineers and sales persons will specially design for you in accordance with your raw materials, self construction of factory building and capital budget.