Introduction of Rotary Drum Screener

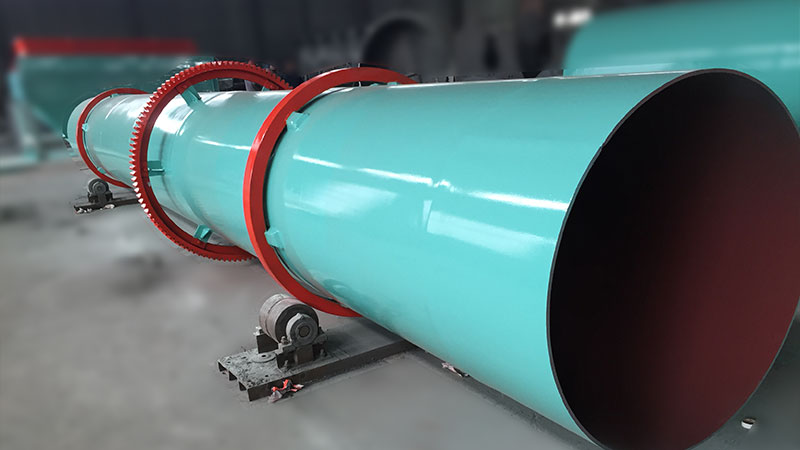

Rotary drum screen, also called fertilizer screening machine or rotary screener, is a key equipment for sieving organic fertilizer and compound fertilizer. It is used in grouping finished products and unqualified products which need to reprocess. The screening machine can classify the finished products according to their grade as well. The rotary drum screen basically consists of rotary drum, framework, funnel, retarder and engine. When materials pour into rotary drum through feed inlet, the screening machine rotates to sieve the materials. The materials rotate with the drum and screen by different sieve to measure up the presetting standard. Selected granules will be sent to the finished products group automatically or by hand. The rotary screen adopts modular screen which is easy to replace or maintain. Rotary screener is an indispensable fertilizer sifting machine for both organic fertilizer and compound fertilizer factories, due to its simple structure, foolproof operation, and steady working performance.

It is used in grouping finished products and unqualified products which need to reprocess. The screening machine can classify the finished products according to their grade as well. The rotary drum screen basically consists of rotary drum, framework, funnel, retarder and engine. When materials pour into rotary drum through feed inlet, the screening machine rotates to sieve the materials. The materials rotate with the drum and screen by different sieve to measure up the presetting standard. Selected granules will be sent to the finished products group automatically or by hand. The rotary screen adopts modular screen which is easy to replace or maintain. Rotary screener is an indispensable fertilizer sifting machine for both organic fertilizer and compound fertilizer factories, due to its simple structure, foolproof operation, and steady working performance.

Structure of Rotary Fertilizer Sifter Machine

1.Framework

The framework of this fertilizer sifter is made of high-quality carbon steel plate, channel steel. It meets the demand of conformity certification and specific techniques.

2.Screen

The screen part adopts modular sieve. The modular sieve is installed on the drum of the principal shaft. Materials are conveyed into the drum through the feed inlet, and the drum rotate to group them efficiently into finished products or unqualified products which need to reprocess.

3.Transmission part

The engine drives the belt pulley, vee belt, transmission reducer to rotate the principal shaft to work. The structure of the transmission part is simple and convenient to assemble and maintain.

Installation of Rotary Drum Screen

The fertilizer sifter machine is composed of mainframe, grading room, screen rotor structure, a reducer, input shaft with a pulley, output shaft with coupling, main engine equipped with a pulley, pins, triangular belt, modular sieve etc.

The rotary drum screen has been debugged before leaving factory. All of our screening machine are qualified and have a certificate of quality. While sometimes you still need to regulate the machine before put into use in accordance with your need. If you find the grading of material is unequally, you need to replace the modular sieve for normal use.

Tips of Rotary Screener

1.Turn on the rotary screen without any load. It is forbidden to put on materials on it before you energize the rotary screener in case of any damage of the sieve machine.

2.Check out the bolt before you start this rotary sieve machine.

3.Check the oil level of bearing pedestal and reducer.

4.You should finish the screening process before you stop the screening machine to ensure there is nothing in the rotary drum.

Rotary drum screen, also called fertilizer screening machine or rotary screener, is a key equipment for sieving organic fertilizer and compound fertilizer.

It is used in grouping finished products and unqualified products which need to reprocess. The screening machine can classify the finished products according to their grade as well. The rotary drum screen basically consists of rotary drum, framework, funnel, retarder and engine. When materials pour into rotary drum through feed inlet, the screening machine rotates to sieve the materials. The materials rotate with the drum and screen by different sieve to measure up the presetting standard. Selected granules will be sent to the finished products group automatically or by hand. The rotary screen adopts modular screen which is easy to replace or maintain. Rotary screener is an indispensable fertilizer sifting machine for both organic fertilizer and compound fertilizer factories, due to its simple structure, foolproof operation, and steady working performance.

It is used in grouping finished products and unqualified products which need to reprocess. The screening machine can classify the finished products according to their grade as well. The rotary drum screen basically consists of rotary drum, framework, funnel, retarder and engine. When materials pour into rotary drum through feed inlet, the screening machine rotates to sieve the materials. The materials rotate with the drum and screen by different sieve to measure up the presetting standard. Selected granules will be sent to the finished products group automatically or by hand. The rotary screen adopts modular screen which is easy to replace or maintain. Rotary screener is an indispensable fertilizer sifting machine for both organic fertilizer and compound fertilizer factories, due to its simple structure, foolproof operation, and steady working performance. Structure of Rotary Fertilizer Sifter Machine

1.Framework

The framework of this fertilizer sifter is made of high-quality carbon steel plate, channel steel. It meets the demand of conformity certification and specific techniques.

2.Screen

The screen part adopts modular sieve. The modular sieve is installed on the drum of the principal shaft. Materials are conveyed into the drum through the feed inlet, and the drum rotate to group them efficiently into finished products or unqualified products which need to reprocess.

3.Transmission part

The engine drives the belt pulley, vee belt, transmission reducer to rotate the principal shaft to work. The structure of the transmission part is simple and convenient to assemble and maintain.

Installation of Rotary Drum Screen

The fertilizer sifter machine is composed of mainframe, grading room, screen rotor structure, a reducer, input shaft with a pulley, output shaft with coupling, main engine equipped with a pulley, pins, triangular belt, modular sieve etc.

The rotary drum screen has been debugged before leaving factory. All of our screening machine are qualified and have a certificate of quality. While sometimes you still need to regulate the machine before put into use in accordance with your need. If you find the grading of material is unequally, you need to replace the modular sieve for normal use.

Tips of Rotary Screener

1.Turn on the rotary screen without any load. It is forbidden to put on materials on it before you energize the rotary screener in case of any damage of the sieve machine.

2.Check out the bolt before you start this rotary sieve machine.

3.Check the oil level of bearing pedestal and reducer.

4.You should finish the screening process before you stop the screening machine to ensure there is nothing in the rotary drum.

Working Videos of Rotary Sieve Machine, Rotary Screening Machine in Organic Fertilizer Production Line

Technical Data of Fertilizer Sifting Machine

|

Model

|

Overall Dimensions L x W x H(mm)

|

Prod Capacity (t/h)

|

Power (kw)

|

Inclination(0)

|

|

AZS-GTSF-1.0X3

|

3800x1300x2600

|

1-3

|

3

|

2-2.5

|

|

AZS-GTSF-1.2X4

|

5000x1600x3000

|

2-5

|

5.5

|

2-2.5

|

|

AZS-GTSF-1.5X5

|

6300x1880x3450

|

3-7

|

7.5

|

2-2.5

|

|

AZS-GTSF-2.0X8

|

9800x2700x4700

|

11/15

|

2-2.5

|