Introduction on Disc Mixer Machine

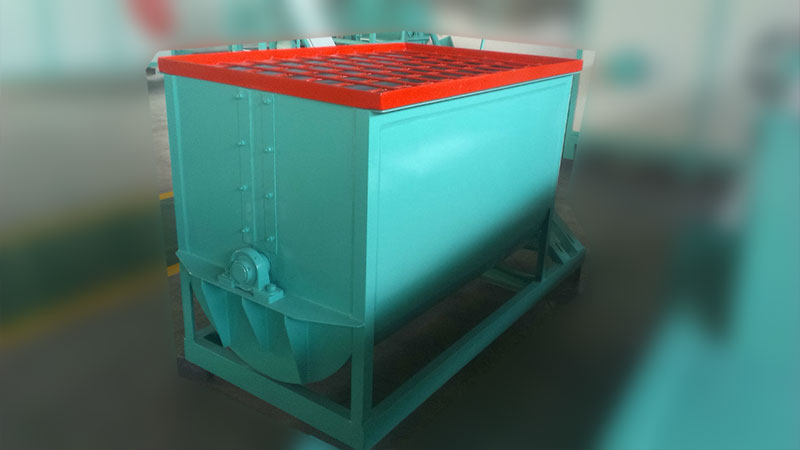

Disc mixer is used to blend raw materials of both compound fertilizer and organic fertilizer. It can be used separately, or connected with other fertilizer

Structure and Working Principle of Pan Mixer

All the parts of this fertilizer mixing equipment are fixed on frame which is welded by quality carbon steel and U-steel. It passes the strict product certification and special manufacturing requirements to ensure the normal and continuous working of this machine. The whole mixing process is driven by the main shaft after starting the motor. There are several stiring spades welded on the main shaft and small shovels are set on each stiring spade. The arms and shovels fully mix the raw materials in the disc. Open the discharging port under the disc, the materials will be discharged and fall on the belt conveyor to be sent to the fertilizer granulator.

Features of Pan Fertilizer Mixer Blender

1.It pays attention to each detail. Outside, it is good looking; inside, it adopts latest rotor structure, the minimum clearance between the rotor and shell can be adjusted to near zero, which efficiently decreases the residue of materials.

2.It stresses the smoothness of the whole working process. The pan mixer adopts polypropylene plate or stainless steel inner lining, which prevents raw materials from adhering on the wall, and has better abrasion resistance.

3.It can either work independently or matched with fertilizer production line.

Cautions for Test Run of High Speed Blender

1.Start the machine without any raw material.

2. Ensure the raw material without any metal scrap.

3. Before starting the machine, check whether all the bolts are tight.

4. Check whether the oil in the bearing block and reducer reaches to the standard level.

5.When start the main motor, to see if the rotation direction is opposite. If opposite, stop the machine immediately and adjust the direction.

6. Stop feeding materials before you stop the machine. It is strictly forbidden to stop the machine with materials in it.

Technical Data of High Speed Fertilizer Blender

|

Model

|

Overall Dimension

(L*W*H)(mm)

|

Output

(t/h) |

Power

(kw) |

Mixer Diameter

(mm)

|

|

AZS-YPWL-1500

|

1600*1600*1550

|

2-4

|

7.5

|

1500

|

|

AZS-YPWL-2000

|

2100*2100*1600

|

3-6

|

11

|

2000

|