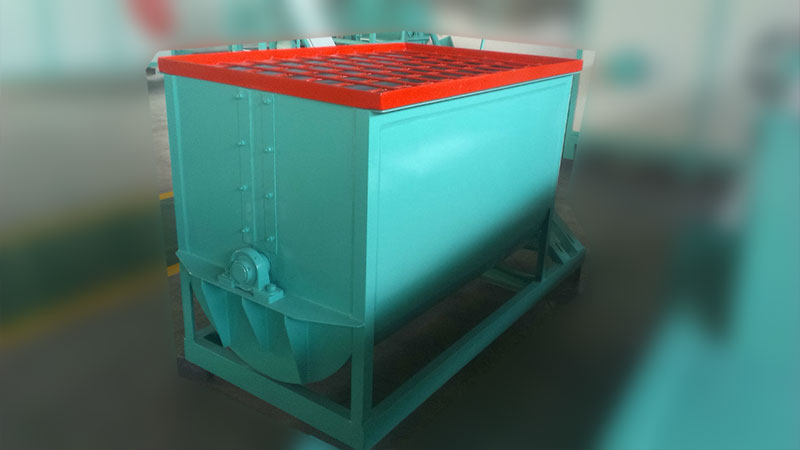

Horizontal fertilizer mixer is a kind of novel mixer machine with high efficiency, used for premix in organic fertilizer and compound fertilizer production. To

Working Principle of Horizontal Mixer Machine

Horizontal Fertilizer blending Machine is made of container, helical mixing blade and transmission parts. The machine uses two relative rotative shafts with spiral blades mounted to mix the materials. As the spiral blades have multiple angles, raw materials can be mixed quickly and effectively, regardless of their shape, size and density. After the materials are fully mixed, open the discharge port under the tank and the materials will be discharged from the blending equipment, and conveyed to the fertilizer granulator.

Features of Horizontal Industrial Mixer Machine

1.This blending machine makes materials get fully mixing, thus greatly improving its mixing evenness and big particles also can be crushed.

2.With improved design, the minimum clearance between the rotor and shell can be adjusted to nearly zero, which can efficiently reduce the amount of residuals.

3.It has a more reasonable structure compared with the old models, which makes it good looking and easy to maintain. At the same time, it adopts stainless steel helical blade and other hard steel for body, ensuring its long service life.

Some Tips for Industrial Mixer Machine Maintenance

1.Lubrication has a close relationship with the bearing, which directly influences its service life and running rate, therefore the lubricating oil must be clean and under a very good sealing condition.

2.The newly installed strake is easy to loosen, which often need checking.

3.Pay attention to whether each part are working normally.

4.Keep the working platform clean in case that the free bearing is unable to move when the mixer meet some impurity substance that can be broken.

5.When the temperature of the bearing is too hot or the gear has noise in working process, the operator needs to stop at once, making check and eliminating this problem.

Specifications of Horizon Fertilizer Mixer

|

Mode of Twin Shaft Mixer

|

Overall Dimension

(L*W*H)(mm)

|

Output

(t/h)

|

Power

(kw)

|

Model of Single Shaft Mixer

|

Overall Dimension

(L*W*H)(mm)

|

Output

(t/h)

|

Power

(kw)

|

|

AZS-SZJB-40

|

3800*1250*750

|

3-7

|

11

|

AZS-WSJB-70

|

2330*1130*970

|

2-3

|

11

|

|

AZS-SZJB-60

|

4400*1500*10500

|

5-10

|

18.5

|

AZS-WSJB-90

|

2330*1070*1200

|

3-5

|

15

|