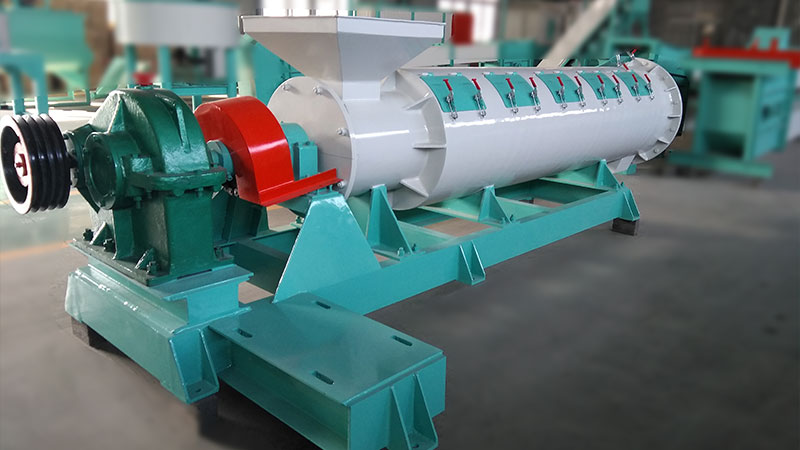

Introduction of Dedicated Organic Fertilizer Making Machine

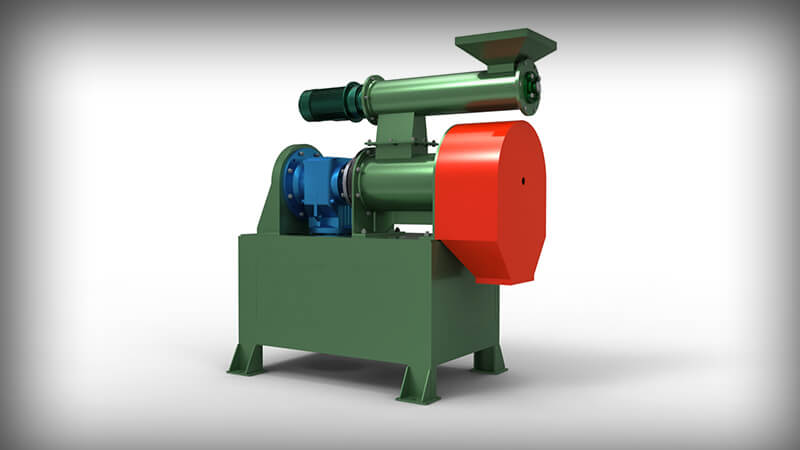

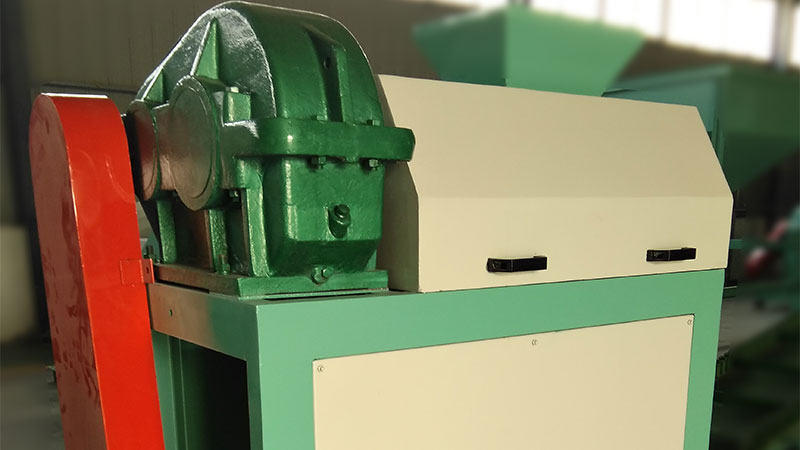

Working Principle of Organic Fertilizer Dedicated Granulator

Characteristics of New Type Organic Fertilizer Making Machine

1.Shape of finished fertilizer granules is Spherical.

2.High organic matters content, which can be 100%. It makes pure organics granulation come true.

3.The finished products are with cohesive structure. They can be screened by rotary drum sifting machine directly, with high production efficiency.

4.This organic fertilizer granule machine adopts no-drying fertilizer production process-the moisture content of raw materials can be 20%-40%, to some extent, greatly reduce manufacture cost.

5.High granulation rate-higher than 80%-90%. One of the reason why we call it New Type Organic Fertilizer Machine is because it adapts to a variety of different formulas.

6.Compared with disc granulator and rotary drum granulator, new type organic fertilizer granulator has higher compressive resistance.

Application of New Type Organic Fertilizer Making Machine

1.Animal manure fertilizer production line: pig manure organic fertilizer production process, chicken manure bio fertilizer production technology, cow dung organic fertilizer production line etc.

2.This organic fertilizer making machine has a wide application of raw materials, such as peat, sewage sludge, livestock manure, lignite, straw fermentation and so on.

3.New type organic fertilizer granulation machine can be used to manufacture not only organic/bio organic fertilizers, but feed pellets with cornmeal, soy flour and maize meal as raw materials.

4.It also can be used to granulate organic municipal waste, such as animal hair, mushroom residue, WWTP sludge (heavy metal element doesn’t exceed).

Working Video of Organic Fertilizer Granulating Machine

Parameter of New Type Organic Fertilizer Granulator

|

Model

|

Prod Capacity(t/h)

|

Power (kw)

|

Dimension L x W x H(mm)

|

|

AZS-JCZL-60

|

2-3

|

37

|

3550x1430x980

|

|

AZS-JCZL-80

|

3-5

|

55

|

4160x1660x1170

|