Introduction of Multi-function Flat Die Extrusion Granulator

The reason that we say this fertilizer granulator is multi-functional is because it can not only be used independently to manufacture cylindrical organic

In flat die extrusion process, organic/bio-organic fertilizers are uniform in composition and shape. The diameter of fertilizer pellets differ, with utilization of different dies. Customers can choose whichever die they need in the whole manufacturing process. Due to low moisture content, all fertilizer pellets are easy to storage and transport, slow to release in soil, thereby further increasing the VCR. It is the most popular fertilizer machinery in livestock farm. Farmers purchase the flat die fertilizer granulator to manage animal manure and make them into manure pellets, so we also call it: manure pellet machine.

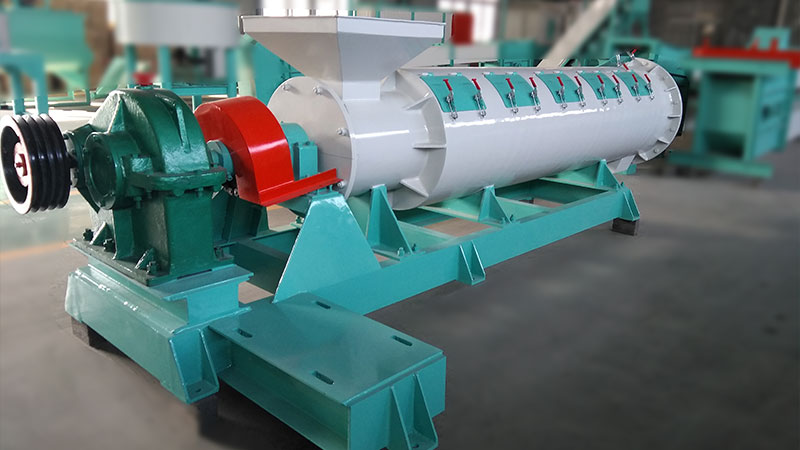

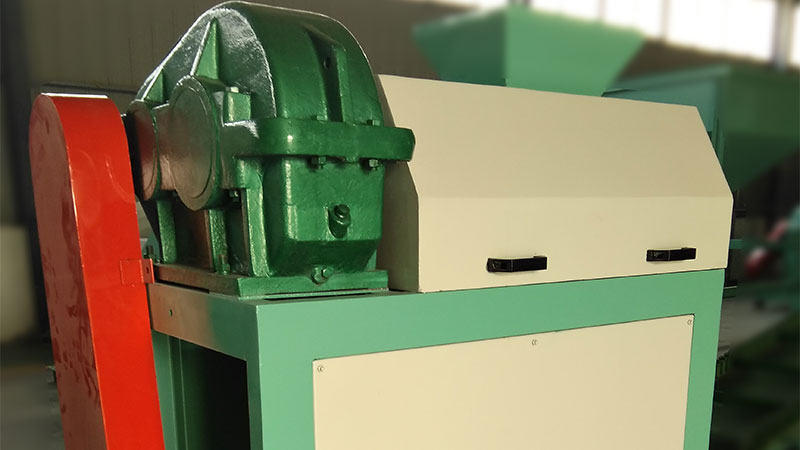

Structure and Features of Flat Die Fertilizer Granulator

1. Being very different from other Extrusion-Formation equipment, flat die extrusion granulator adopts inclined wheel, two sides of which keep the same rotation speed with the dies. Therefore, there is no friction between wheel and die. The reasonable design, to a large extent, decreases energy consumption, prolongs the lifespan of dies, reduces the production cost.

2. There are more than 20 kinds of dies with different diameter. Customers have a deadly option. They can changes the dies while processing different raw materials.

3. During extrusion process, the high temperature won’t be easily transferred to bearings chamber, promising all bearings working normally under low temperature.

4. This organic fertilizer granulation machine can be used in organic fertilizer plant and bio fertilizer production line, but it should be combined with high moisture materials crusher.

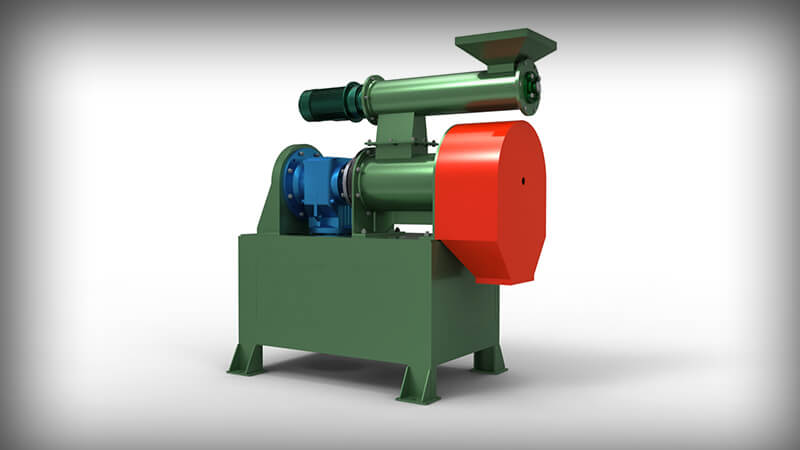

Working Process of Flat Die Organic Fertilizer Making Machine

Flat die extrusion granulator is based on circular motion, powered by electric motor. With frictional forces, rollers rotate. Temperature rises when dies and roller rotating. Organic materials are extruded into fertilizer pellets from dies under the squeezing force and high temperature gelatinizing. Then cutters break the length of those fertilizer pellets.

Flat Die Extrusion Granulator Application

◇ Low temperature granulation: organic fertilizer manufacturing plant, bio fertilizer plant, bio-bacterial manure fertilizer production process etc.

◇ Organic materials, such as animal manure, crop straw, rich hull, product screenings, soybean meal, sewage sludge etc.

◇ It is most suitable for handling animal waste in chicken farm and pig farm. At the same time, the flat die organic fertilizer granulation machine can process soya bean cake or hay into feed pellets. Thus, this fertilizer granulator is a necessary equipment in small and medium livestock farms.

Technical Data of Flat Die Extrusion Granulator

|

Model

|

Overall Dimension

LxWxH (mm)

|

Production Capacity (t/h)

|

Power (kw)

|

Granulation Rate (%)

|

Particle Temperature (℃)

|

Particle Diameter (mm)

|

|

AZS-KP-40

|

1200x650x1450

|

0.75-2

|

15

|

>95

|

<30

|

3-30

|

|

AZS-KP-60

|

1800x900x1850

|

1-3

|

22

|

>95

|

<30

|

3-30

|