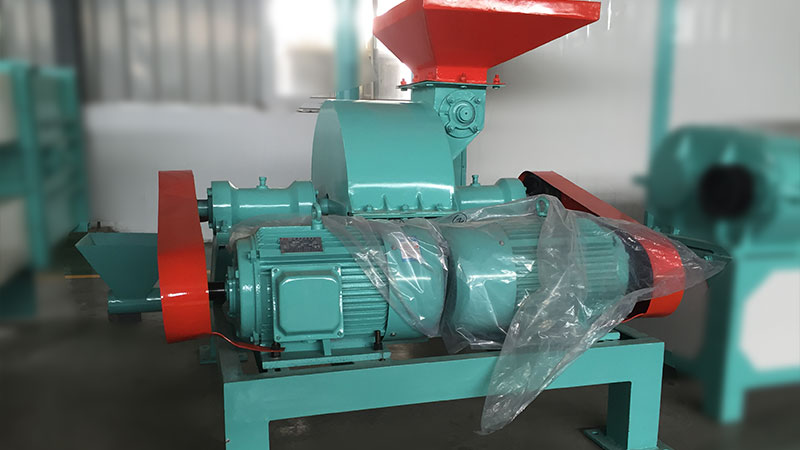

Introduction of Dust-free Cage Mill

Features of Efficient Cage Mill

● It works quietly, no vibration and no noise. You can work in a comfortable surroundings.

● It has a small body and runs smoothly, which occupies little space.

● This fertilizer disintegrator is friendly. Anybody can easily learn to how to operate and doesn’t need to worry about their safety.

● It has powerful function, which is capable of producing a variety of product gradations by changing the crusher speed.

● It can keep you company for many, many and many years because it adopts high-strength durable carbide.

Working Principle of Cage Organic Fertilizer Crusher

This organic fertilizer crusher is powered by electric motor and installed on iron bracket with rotors inside. It makes use of reduction system to realize the normal rotating of central separation cylinder. The central separation cylinder is effectively a crushing net made of several flat rings and it is in a declining state. The material flows like water from the upper end of the central separation cylinder and passes through the crushing net, finally the big particles entering the crusher. During the rotation, the dust particles are thrown to the inner wall of the outer cylinder without speed. Under the action of gravity, the dust particles fall down along the wall of the cylinder and go out from the dust discharging hole, thus producing no dust and keeping the crushing hole unobstructed.

Application of Functional Fertilizer Grinder

It is the first choice when people need to crush raw materials with high hardness like urea. In fertilizer line, it is usually used to crush chemical fertilizers with moisture below 6%.

This materials crusher is also use to crush a variety of organic materials in fertilizer production line. The reason why this fertilizer disintegrator is popular is because it is completely designed out of customer’s need. It is of quality materials and can be customized according to different raw materials. With professional attitude and considerate service, you can purchase it without worry no matter where you are from.

Technical Parameter of Materials Crusher

|

Model

|

Overall Dimension

(L*W*H)

|

Production Capacity

|

Power

|

Rotating speed

|

|

AZS-NSFS-60

|

1380X1350X1260 mm

|

1-3 t/h

|

15+15 kw(2 motors)

|

2000(r/min)

|

|

AZS-NSFS-80

|

2200X1750X1850 mm

|

2-5 t/h

|

22+18.5 kw(2 motors)

|

2000(r/min)

|