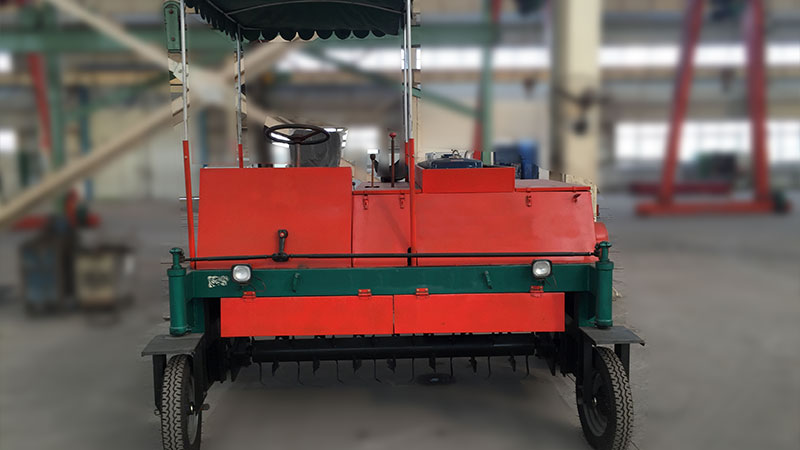

Introduction of Self-propelled Windrow Turner

As the major part of the whole sets for manufacturing organic fertilizer and bio fertilizer, self-propelled compost turner adopts four-wheel driving  structure which can move forward, backward or make a turn just by one operator. During the operation, the whole trolley straddle son the strip foundation of raw material. After stirring, ruffling, blending the material by the revolving cutter arbor, a new strip of fertilizer heap come into being.

structure which can move forward, backward or make a turn just by one operator. During the operation, the whole trolley straddle son the strip foundation of raw material. After stirring, ruffling, blending the material by the revolving cutter arbor, a new strip of fertilizer heap come into being.

The self-propelled compost turner can work in an open area as well as in a greenhouse. Its technical breakthrough lies in its crushing function in the later aerobic fermentation stage. When the self-propelled windrow turner dewater the raw material, the cutter arbor equipped with crushing device could crunch the dried material which coagulates together because of dewatering. Such a design not only saves money spending on fertilizer crushing machine (high moisture materials crusher, for example, it is usually used to grind organic materials), but also raise the crushing efficiency, lower the cost, and solve the problem of production capacity constraining by the crushing machine.

This windrow turner has been sold to Nepal, and other countries!

Features of Self-propelled Compost Turner

1.The composting equipment is designed on the basis of microorganism aerobic fermentation. In accordance with the theory of aerobic fermentation, it offers a good condition for fermentation.

2.This bio fertilizer windrow turner can effectively blend various organic waste, such as livestock dung, microbial preparation and crop residues powder together. It provides a better aerobic environment for aerobic fermentation. For example, if you ferment loose material, like cow dung, you just need to regulate the temperature within the range of 60 – 70 degree for three or four days.

3.Self-propelled compost turner is a powerful organic fertilizer machine with low consumption, high production capacity, and low running cost. According to the parameters of this composting equipment, it can stir 400 -500 cubic meters one hour (equivalent to the workload of one hundreds

4.The self-propelled compost turner owns a scientific structure, and it has a great working performance. This windrow turner is easy to operate, and adaptive to working site. The spare parts are all normalized except the main framework.

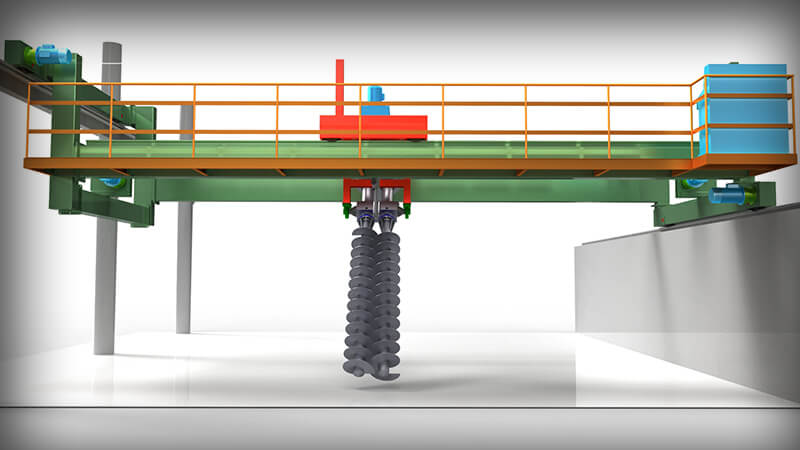

Working Principles of Self-propelled Windrow Turner

The FYD series organic fertilizer windrow turners adopt four-wheel self-propelled design, which can operate by one worker. The machine straddle on the raw material heap when working, and generates new strips of bio fertilizer. Its special crushing function in the subsequent aerobic fermentation stage is cost-effective. The diesel engine conducts the power to the transmission, then the operator will operate this windrow turner to stir the raw material.

Application of Self-propelled Compost Turner

1.Make sure the ground is solid and level the working site before work. The roughness of the earth should keep within 50mm.

2.The width of the material heap must keep the specified width. The height can increase less than 100mm. There is no limitation on the length.

3.Both ends of the material heap should leave space more than 10m considering the turning of this organic fertilizer machine. The distance between two material heaps should keep more than 1m.

4.Don’t drive the compost turner as a vehicle or a lorry.

Technical Data of Self-propelled Compost Turner

|

Model

|

9AZS-FYD-2000

|

9AZS-FYD-2300

|

9AZS-FYD-3200

|

|

Width of the pile (mm)

|

2000

|

2300

|

3200

|

|

Height of the pile (mm)

|

500-800

|

600-1000

|

1300-1600

|

|

Plies distance (m)

|

0.5-1

|

0.5-0.8

|

0.8-1

|

|

Power

|

33HP(water-cooling, electric start)

|

58HP(water-cooling, electric start)

|

150HP(water-cooling, electric start)

|

|

Processing capacity (m³/h)

|

400-500

|

500-700

|

1000-1500

|

|

Driving mode

|

3 gear forward, 1gear backward

|

3 gear forward, 1gear backward

|

crawler walking, spot steering

|