Introduction of Groove-type Compost Turner

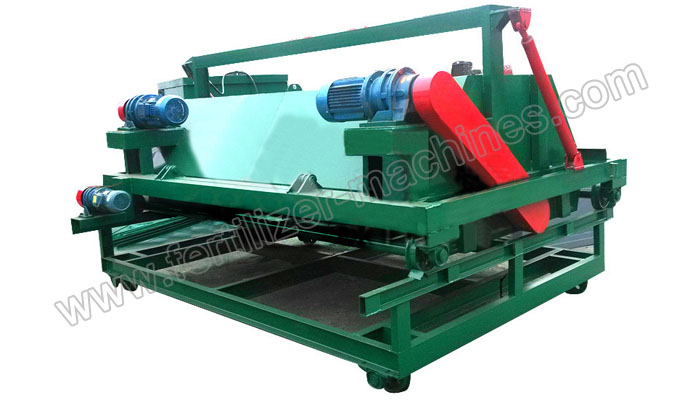

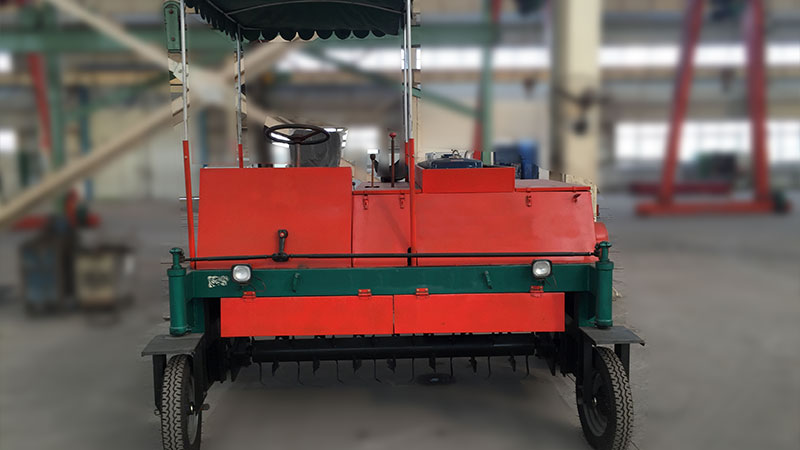

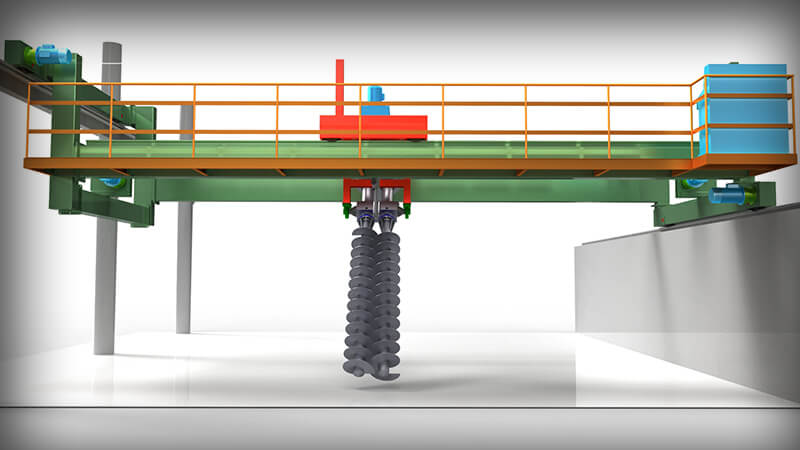

Groove-type compost turner is a branch of compost turner, which is also called windrow turner or lane turner sometimes. There are 2 kinds of groove compost turner, one with hydraulic equipment, the other kind with no hydraulic system. Hydraulic equipment drives the whole lane turner up and down to evenly turn the organic materials.

Our groove type windrow turner applies to ferment and compost all kinds of organic waste, such as sludge, crop residues, filter mud of sugar refinery, livestock and poultry dung. We can see groove-type compost turner in organic fertilizer production line, organic-inorganic fertilizer plant, sludge wasteyard, garden spot, and agaricus bisporus farm etc. Groove-type compost turner can be equipped with solar-fermentation chamber, fermentation tank, etc.

Features of Groove Type Windrow Turner

Groove-type windrow turner consists of transmission, bont, running gear, turner and carrying cart. The electric motor energize the cycloidal pin-wheel speed reducer, then surpass to the sprocket and the drum. The stirring blades twisted on the drum,which help equably stirring the stuff in the fermentation tank within the range of 0.7-0.12 m. All of this guarantee the stuff can be thoroughly exposed to the air, and ferment the stuff to their fullest. It is a great fermentation and organic compost turner machine.

As the core equipment of industrial harmless treatment, the lane turner is born to work in fermentation tank in animal husbandry industry, municipal waste disposal factory. The compost turner is efficient, cost-effective, automated machine due to its advanced structure, and it’s a kind of marketable fermentation machine.

Safety Operation Specification of Lane Turner

1.The operator of the compost turner must in a good shape. It is forbidden to operate the fermentation machine after drink.

2.Before staring the machine, the operator should ring the siren to alarm everybody who is in the operation range.

3. It is prohibited that someone might pass by the operation range of lane turner when it is working.

4.If you need to inspect or lubricate the fermentation machine, you must stop the machine first.

5.We should operate the machine at its specified speed. If you are not an qualified operator, you mustn’t operate the fermentation machine.

6.The rails of the groove-type compost turner must be fully on the earth.

7.Cut the power when you need to replace the trunking or the electric cable.

8.Be careful when you use the winch in case of lifting too low or too high. If the winch lift too low, it might be damage the blades. If the winch lift too high, if might be destroy

the winch and bearing pedestal of the windrow turner.

9.Examine the steel ropes of the winch regularly, and change the wire rope if necessary.

Advantages of Organic Fertilizer Fermentation Machine

1.The compost turners rely on rails for moving forward or backward, which is reliable and cost-effective.

2. The organic fertilizer machine adopts bridge-structure, including stretch-cross type and longitudinal-cross type. It means we can dump the stuff vertically or laterally.

3. Only a small part of the organic fertilizer machine will directly contact the material, and its easy to maintain and have a long service life.

Working Video of Groove-type Compost Turner Machine

Technical Data of Groove-type Windrow Turner

|

Model

|

AZS-FJ6000×350

|

AZS-FJ4000×1050

|

AZS-FJ4000×350

|

|

|

Matched power(kw)

|

25.74

|

41.5

|

10

|

10

|

|

Working speed(m/h)

|

50

|

50

|

50

|

50

|

|

No-load speed(m/h)

|

100

|

100

|

100

|

100

|

|

Size of fermentation tank

(w×h )mm |

6000×1050

|

6000×350

|

4000×1050

|

4000×350

|

|

External dimension

(mm) L×W×H |

4670×3920×2740

|

4670×4800×3200

|

4670×3920×2740

|

4700×4800×3200

|

|

Lift height of gear(mm)

|

1400

|

1500

|

1400

|

1500

|

Technical Data of Hydraulic Groove-type Compost Turner

|

Model

|

AZS-XSCSFD03

|

AZS-XSCSFD04

|

|

Power(kw)

|

15.5

|

22.75

|

|

Working speed(m/h)

|

50

|

50

|

|

Size of fermentation tank(w*h )mm

|

3000×700

|

4000×900

|

|

Lift height of mixing gear(mm)

|

700-1000

|

800-1100

|