Slope Screen Manure Separator Machine

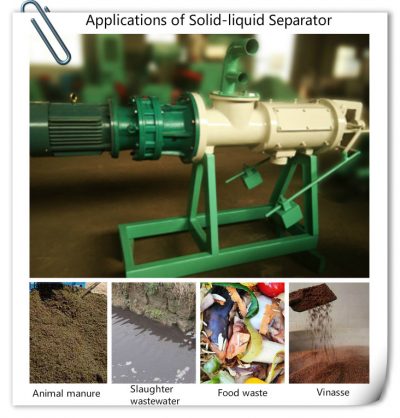

Slope screen manure separator is common mechanical equipment in farms that can effectively separate manure from solid and liquid. It is widely used in the separation of slag-liquid of high concentration organic sewage such as animal manure, wine tank, dregs, starch residue, sauce residue of various intensified farms which raise pigs, chickens, cattle and horses.

Slope Screen Solid-liquid Separator Characteristics

1, 304 stainless steel construction. Corrosion resistance. Long service life.

2, Simple design, no moving parts, low maintenance, and minimal wear and tear.

3, Efficient screen design, whose opening sizes were carefully dimensioned, in order to produce a great quality of the recycled liquid.

4, Integrate transmission, pressing, dewatering, and sand removal. Automatic liquid level control

The Design Principle of The Slope Screen Manure Separator

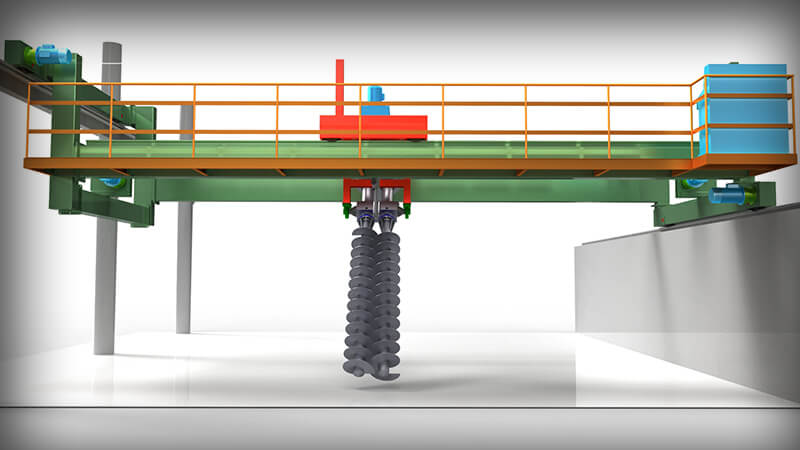

It includes a vibration system, a feeding extrusion system, and an automatic washing system. It is an effective way to effectively treat the manure and liquid discharged from livestock and poultry farms for solid-liquid separation. The separated feces can be directly packaged and transported, and the separated liquid can be transported to the anaerobic tank, which can be processed into biogas through anaerobic treatment for domestic use.

| Model | SSM20 | SSM40 | SSM60 |

| Main Power | 3Kw | 4Kw | 5.5Kw |

| Pump Power | 3Kw | 3Kw | 4Kw |

| Mixing Power | 3Kw | 3Kw | 3Kw |

| Vibrating Power | 30W | 60W | 60W |

| Voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Base Loading Area | 900*1000mm | 1210*1000mm | 1300*1000mm |

| Dimension | 1900*1100*1600mm | 2200*1150*1600mm | 2450*1150*1750mm |

| Raw Materials | Stainless Steel 304 | ||

| Working Principle | Screw extrusion | ||

| Appendix | Mixer, sewage pump, stainless steel control cabinet, steel wire hose, PVC return valve | ||

| Working Process | The pump drives the material in the manure tank into the main machine, and squeezes the moisture in the material through the screen through the screw thrust and the pressure of the spring cover plate, and the dehydrated material is discharged through the dry material and squeezed out. | ||

| Capacity | 15-25m³/hour | 30-40 m³/hour | 55-60 m³/hour |

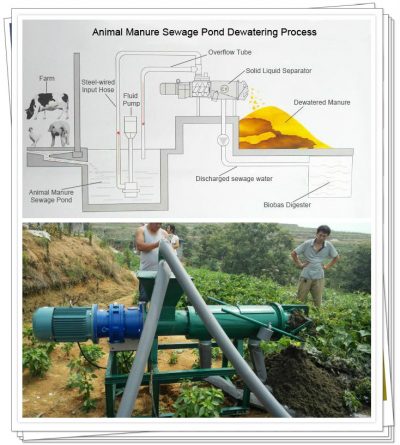

This solid-liquid separator is widely applied for the dewatering process of animal manure in intensive livestock and poultry  farms (including pig manure, cow dung, chicken manure and other livestock fecal dehydrating). Besides, it is also used into the slag liquid separation of vinasse, starch pulp, soy sauce residue and other high concentration organic wastewater.

farms (including pig manure, cow dung, chicken manure and other livestock fecal dehydrating). Besides, it is also used into the slag liquid separation of vinasse, starch pulp, soy sauce residue and other high concentration organic wastewater.

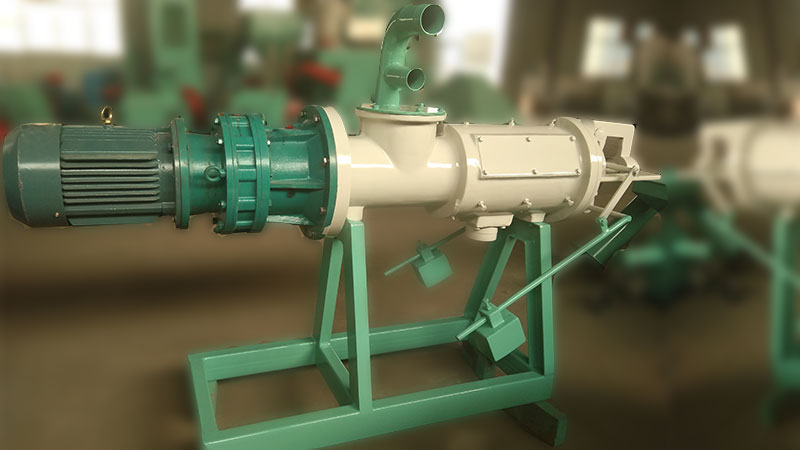

Working Principle of Solids and Liquid Separator

This solids and liquid separator adopts the principle of screw extrusion dehydration. Firstly, the original manure in cesspool is pumped to the solid-liquid separator by the matched non-blocking submerged pump, and then the auger gradually pushes the original animal manure to the front of the machine, while continuously increasing the pressure of machine leading edge, forcing the moisture in the manure extruded from the equipment and discharged through drain-pipe under the action of the side pressure belt filter. In a word, this machine is able to separate dry manure with low moisture content (less than 50%) and fecaluria from original manure, reaching the efficient treatment and rational utilization of resource.

Features of Animal Manure Dehydrator

This solid-liquid separator has the characteristics of high automation level, simple operation, easy maintenance, large daily processing capacity and lower power consumption, all of which make it suitable for continuous working. Moreover, with small outer shape and high separation accuracy, this equipment can save space and can greatly improve the efficiency of dewatering  treatment of livestock and poultry manure. In general, our animal manure dehydrator is mainly composed of a solid-liquid separator main engine, a feed pump, a water pipe, a distribution box and the like.

treatment of livestock and poultry manure. In general, our animal manure dehydrator is mainly composed of a solid-liquid separator main engine, a feed pump, a water pipe, a distribution box and the like.

After dehydration, animal manure has the following advantages and efficacy: The dry manure after dehydrating and separating is almost odorless and its viscosity is small, which makes it appropriate to be used as base fertilizer and topdressing, and also as raw materials of producing organic fertilizer. With long and stable fertilizer efficiency, the processed manure supplements the soil with nitrogen, phosphorus, potassium and trace elements, enriches the soil organic matter and overcomes the shortages that making the soil saline-alkali compaction caused by the common application of chemical fertilizers, playing an important role in improving the soil. It has been proved by practice that it is better than chemical fertilizers under the same growth conditions. In the meantime, this machine has been a significant part in the establishment of manure organic fertilizer production plant, helping reducing moisture of organic raw materials before making organic fertilizer.