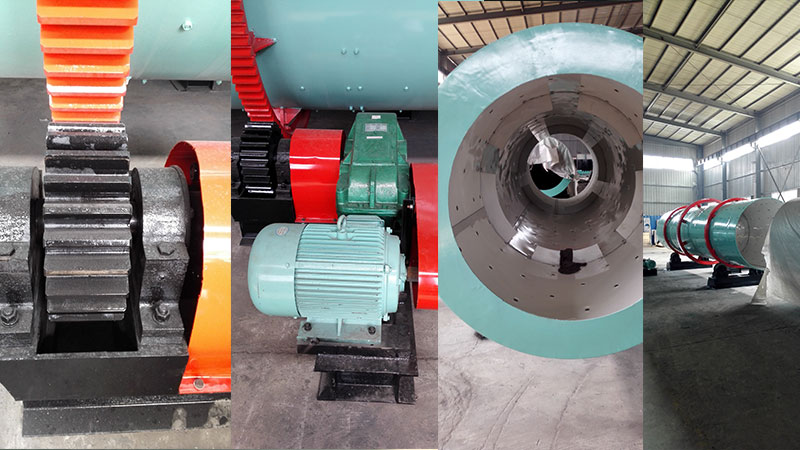

Horizontal mixer makes materials fully mixed, thereby improving the mixing uniformity. It is characterized by reasonable overall structure and easy installation and maintenance.

It is an extremely important regular work with machine maintenance. Horizontal fertilizer mixer should work with good operations and maintenance. The full-time staff on duty are supposed to check the machine at fixed periods. How to maintain the machine in the process of fertilizer mixer use? What is the installation notes of the horizontal mixer machine?

Installation Notes:

a.The device should be installed on horizontal place without gradient. And fix the machine with foundation bolt.

b. The installation personnel should pay attention to machine assembly angle. Generally speaking, be sure that the machine body remains vertical to the ground.

c. After installation, check all parts of bolts without loosening.

d. Choose power line and control switch according to power equipment configuration.

e. After check off, keep the machine running no-load. If being in normal condition, then it can be used in organic fertilizer production line.

Horizontal Mixer Maintenance:

1. Bearing supports the entire load of the machine, so good lubrication has a great influence of the bearing life. It directly affects the life and the operation rate of the machine, which requires injecting the clean lubricating oil and good seal. It contains mainly some of oiling places, such as rolling bearing, all wheel gears, live bearing and sliding plane.

2. The newly installed tire is prone to loosen, so it should always be checked.

3. Check all parts of the machine, ensuring regular work.

4. Pay attention to check the wear degree of wear-out part, and change damaged parts in time.

5. The plane, putting the active device chassis, should remove dust to avoid living bearing immobility during work.

6. When bearing temperature rises, it should immediately stop machine running and find out reason to trouble shoot.

7. If it appears impulsive sound during the rotation of the gear, work man should stop the machine and solve the problem.

FAQs:

1.How to place horizontal mixer?

Horizontal mixer should be set at a flat position, with square wooden paving around the axle, so that the tire is put without foundations, to prevent from movement during machine running.

2. What do the work man need to notice while testing?

Horizontal mixer should be implemented secondary leakage protection. Connected to power, it is necessary to carefully check the wiring. Giving a trial run, be sure it is in normal run model before using the machine. The worker should check mixer drum speed whether it meets normal demand. In general, empty vehicle speed is faster 2 to 3 revolutions slightly than heavy vehicle(after charging). When there is a very big difference in rotate speed, the worker can adjust the ratio of wheel and drive wheel.

3. How to check rotation direction?

The rotation direction of mixing drum should be consistent with arrow pointing direction. Otherwise, it should be considered to correct electrical wiring.

4. How to check parts of horizontal mixer?

Check whether the drive clutch and brake are active and reliable. To make sure it is in absence of obstructions around the machine and in good lubrication condition of every part.

5.What should pay attention to at startup and power-off?

After starting up, look over every part of horizontal fertilizer mixer, ensuring it can work properly. When the machine shuts down, check whether the agitator blade is bent and screws are loose.

6.How to clean the machine?

When the materials are crushed or the machine stops run over one hour, it should be cleaned fully. Except from cleaning excess materials, rinse slurry thoroughly with water after starting up the machine. The cylinder may not have water, to prevent impeller blade and charging barrel rusting. It should also be packed deposition outside the mixing tube in order to keep the machine clean and intact.

7.what is the matter needing attention after work?

After work, the power supply worker should switch off power source, and lock the switch box to make sure safety.